We will be exhibiting once again at the premier Composites Expo at SAMPE 2019 – Long Beach, CA. We will be there for you to discuss your Oven Control, Autoclave Control, or Hydraulic Press Control needs. Come by and say hello to Tom, Eric, and Allen at Booth # F29.

For more information contact us or visit sampeamerica.org.

Celebrating SAMPE’s 75th Anniversary, SAMPE 2019 will be held in Charlotte, NC for the first time, allowing SAMPE to showcase the rich offerings of textile and reinforcement technology available in Charlotte and the entire southeastern region of the US. Much of this legacy technology is reinventing itself to become a key contributor to today’s advanced materials marketplace. The technical program content will range from introductory level technology overviews for early career attendees as well as those new to the advanced materials & processes industry to in-depth presentations and panel discussions for the most seasoned technologists.

The conference will include some regional programming that highlights some of the southeastern core businesses. The region is the longtime home of NASCAR and automotive racing, embracing advanced materials and processes in their sport. Boeing is growing and expanding in the Carolinas where advanced materials and processes are used daily to build the 787 Dreamliner in Charleston, SC as Boeing’s Chief Technology Officer, Dr. Greg Hyslop, will highlight during his keynote presentation

NEW! This year, the SAMPE Carolinas Chapter is hosting their annual Golf Tournament and Reception 1:00 PM on Thursday, May 23 at the Ballantyne Resort Golf Course coinciding with SAMPE 2019.

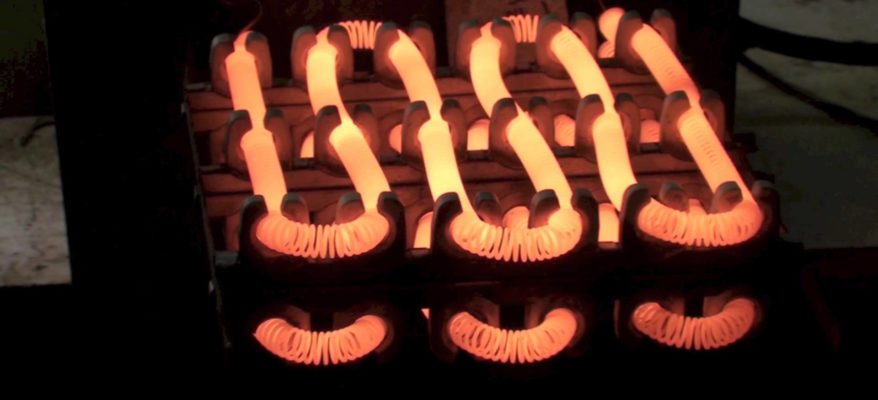

Highlights from SAMPE 2018 Long Beach, CA